Ulendo launches software program expertise able to doubling 3D printing speeds

Ulendo, a College of Michigan spin-out specializing in 3D printing software program, has launched its Ulendo FBS software program device at RAPID + TCT 2022.

This system is designed to allow customers to spice up their print speeds by as much as 100% with out having to degrade half high quality. It really works by modifying a 3D printer’s firmware to compensate for real-world vibrations, and is suitable with any 3D printer that leverages a shifting mechanical printhead.

“If you wish to cut back vibration in a shifting object, most instances you are able to do that by slowing down. However as 3D printing is already very sluggish, that answer creates one other drawback,” mentioned Chinedum Okwudire, an affiliate professor of mechanical engineering and founding father of Ulendo. “Our answer permits you to print quick with out sacrificing high quality.”

Doubling print speeds with Ulendo FBS

Extrusion-based 3D printing has come a great distance because the early days, however lots of as we speak’s desktop programs nonetheless have to run at comparatively sluggish print speeds as a result of vibrations generated by the shifting elements. If a machine is printing too quick, customers run the danger of making defects in components.

Construct to deal with the print pace drawback, Ulendo FBS is predicated on a vibration compensation algorithm that works to mitigate the consequences of a system’s troublesome vibrations. In essence, the software program device predicts when a 3D printer could also be about to expertise a vibration and dynamically adjusts the trajectory of the printhead to fight it. As such, printers operating Ulendo FBS can safely improve their print speeds with out worrying about ruining the floor high quality of components.

Okwudire provides, “Say you desire a 3D printer to journey straight, however on account of vibration, the movement travels upward. The FBS algorithm tips the machine by telling it to comply with a path downward, and when it tries to comply with that path, it travels straight.”

The FBS stands for Filtered B Splines, which is the title of the mathematical operate that the software program makes use of to create the vibration compensation instructions.

Increasing the Ulendo ecosystem

Okwudire first obtained the concept for vibration compensation software program when he was working within the typical manufacturing sector. He’d come throughout milling machines that have been continuously vibrating, and couldn’t merely stiffen the machines’ frames to dampen the vibrations.

He began as a professor on the College of Michigan in 2011, the place he lastly had the time and sources to start designing software program particularly for combating machine vibrations. In 2017, one of many graduate college students in his lab managed to implement his software program on a 3D printing system.

Brenda Jones, CEO of Ulendo, mentioned, “Members of the 3D printing business have the identical jaw-dropping response I had after I first heard about how this expertise leads to a printer working at two instances the pace and 10 instances the acceleration.”

Ultimately, Okwudire based Ulendo to commercialize his expertise and even acquired a $250,000 R&D grant from the Nationwide Science Basis’s (NSF) America’s Seed Fund Program final 12 months. A lot of the corporate’s industrial growth was additionally funded through an MTRAC grant from the Michigan Financial Growth Company.

The Ulendo workforce is at the moment engaged on creating the FBS algorithm to be suitable with a wider vary of equipment, together with robots, machine instruments, and different forms of 3D printers. At RAPID + TCT, Okwudire additionally showcased his lab’s newest innovation – SmartScan. The software program device is able to dynamically adjusting a laser beam’s trajectory round to forestall half warping throughout powder mattress fusion 3D printing.

The newest in additive manufacturing software program

The world of 3D printing software program is rife with innovation and this week’s RAPID + TCT 2022 present was chock stuffed with software program information: Materialise showcased the newest iteration of its Magics print preparation program, Dyndrite signed a number of new software program growth partnerships, and Freemelt debuted its new Pixelmelt course of optimization software program.

Materialise additionally not too long ago introduced its new CO-AM open software program platform, a complete 3D printing course of administration device for the commercial sector. The platform is geared toward high-volume producers, and provides a cloud-based methodology of accessing all kinds of software program instruments (together with third-party ones) for planning, managing, and optimizing the 3D printing workflow.

Subscribe to the 3D Printing Trade publication for the newest information in additive manufacturing. You can even keep related by following us on Twitter, liking us on Fb, and tuning into the 3D Printing Trade YouTube Channel.

Searching for a profession in additive manufacturing? Go to 3D Printing Jobs for a collection of roles within the business.

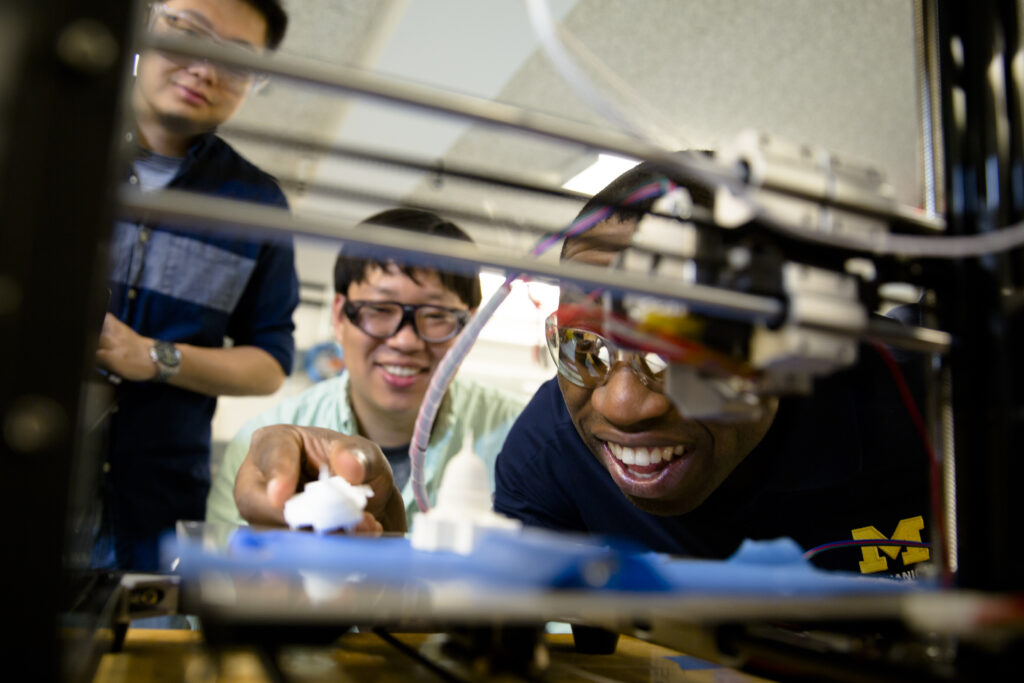

Featured picture exhibits Chinedum Okwudire and college students in his lab on the College of Michigan. Photograph through Evan Dougherty.

https://3dprintingindustry.com/information/ulendo-launches-software-technology-capable-of-doubling-3d-printing-speeds-209620/